Custom Special Shapes Thermal Insulation Polyamide Profile

Basic Info

Model No.: KXT-S90

Product Description

Model NO.: KXT-S90

Material: PA66 GF25

Application: Heat Insulation

Markets Served: Building & Construction

Usage: Internal

Surface Finishing: Finished

Technical Performance: European Standard, Chinese Standard

U-Value Calculation: Service Provided

Authentication: ISO, TUV

Fire Retardant: Optional

Life: > 40 Years

Transport Package: Linear

Origin: Jiangyin, China

Type: Profiled

Forming Way: Extrusion

Material Properties: High Impact

Customized: Customized

Color: Single Color

Applied: for Thermal Break Aluminium Profiles

Raw Material: DuPont PA66, Jushi Short Chopped Fiberglass

Marking: Customized Laser Marking

UV Resistant: Yes

Cutting Dies Service: Available

Trademark: KAXITE

Specification: KXT-S90

HS Code: 3926909090

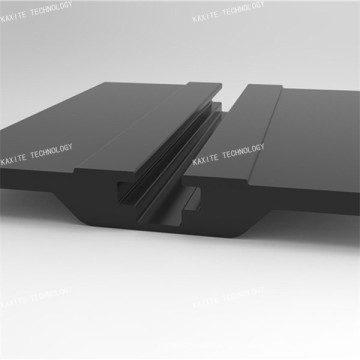

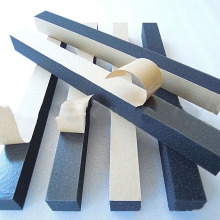

Custom special shapes thermal insulation polyamide profile

MODEL No.: KXT-S90

Custom special shapes thermal insulation polyamide profile for aluminium window profiles. Used in curtain wall system, or in facade system, and being the part of energy-saving window system for reducing heat conduction. Shapes can be customized, we're majored in designing and developing polyamide profiles for window system.

PERFORMANCE

The performance of thermal barrier strips are in line with the Chinese standard GB/T 23615.1-2009 and the European Standard EN 14024:2004, for KAXITE series, the performance is rather higher than the standard value.

| No. | Testing Item | Unit | kaxite Technical Standard | Results from random samples | Conclution |

| 1 | Ash(fiberglass) | % | 25~27 | 26 | qualified |

| 2 | Appearance Quality | surface of smooth, flat, uniform color, no defects that'll effect the usage | Tending to Perfect | qualified | |

| 3 | Density | g/cm3 | 1.30~1.35 | 1.32 | qualified |

| 4 | Linear expansion coefficient | K-1 | (2.5-3.5)*10-5 | 3.48*10-5 | qualified |

| 5 | Vicat softening temperature | ºC | ≥238 | >240 | qualified |

| 6 | Deformation temperature for loading 0.45MPa | ºC | ≥250 | >250 | qualified |

| 7 | Stress via nail shaft | No cracks around the orifice | No cracks | qualified | |

| 8 | Shore hardness | D | 80~85 | 83 | qualified |

| 9 | Unnothed impact strength | KJ/M² | ≥50 | 143 | qualified |

| 10 | Longitudinal tensile eigenvalues in room temperature | Mpa | ≥80 | 81.6 | qualified |

| 11 | Elastic modulus | Mpa | ≥4700 | 4860 | qualified |

| 12 | Elongation at break | % | ≥2.8 | 6.7 | qualified |

| 13 | Transverse tensile eigenvalues in room temperature | Mpa | ≥80a | 100 | qualified |

| 14 | Transverse tensile eigenvalues in high temperature | Mpa | ≥52a | 59.5 | qualified |

| 15 | Transverse tensile eigenvalues in low temperature | Mpa | ≥90a | 105 | qualified |

| 16 | Water resistance Test (Transverse tensile eigenvalues) | Mpa | ≥45a | 53.5 | qualified |

| 17 | Heat aging test (Transverse tensile eigenvalues) | Mpa | ≥70a | 101 | qualified |

Details of related standard:

GB/T 23615.1-2009 Accessorial material for architectural aluminum alloy profiles -- Part 1: Thermal Barrier Strip of polyamide

EN 14024-2004 Metal profiles with thermal barrier -- Mechanical performance Requirement, proof and tests for assessment

YS/T 437-2008 Aluminium profiles moment of inertia calculation methods and computing software requirements

JG/T 174-2005 Thermal barrier strips for construction industry

GB 5237.6 -2012 Wrought aluminium alloy extruded profiles for architecture -- Part 6: Thermal barrier profiles

GB/T 8478-2008 Aluminium windows and doors

GB/T 8484-2008 Graduation and test for thermal insulating properties of doors and windows

JG 175-2011 Insulating aluminum alloy profiles with thermal barrier for buildings

In 2015, we became the leader of the Chinese National Standard Committee (for revising of GB/T 23615.1-2009) .

RAW MATERIALS

For quality, the most important thing is to control the performance of the raw materials, as we have to ensure the expensive but indispensable additives (e.x. Antioxidants & Anti-aging agents) were contained in the mixture. We have our own capacity of granulation for PA66 GF25 and many other kinds of plastic granules. We're the only one who used the technology of Vacuum Drying for the polyamide, which could highly improve the natural performance of the nylon granules.

We have series of brands, corresponding to different raw materials. For domestic series, they will be the domestic new PA66 and short chopped fiberglass, for KAXITE series, they will be the imported Dupond PA66 and short chopped fiberglass, which has rather better performance than the standard required.

CUTTING DIES

Mostly we could finish the development of new products in 15 days.

The hardest thing is not thinking, but realizing. Most customers were upset that nobody could develop the shapes that they designed, some counterparts even came and looking for help to our workshop. We developing and cutting new dies for our customer, of course we never failed to develop any shape for our customers.

DELIVERY

We have more than 40 extruders, production capacity of 550,000 meters per day. For common specifications, they're ready in stock, if customized, mostly the production could be finished in 7 days.

PACKAGES

For all specifications/shapes, they could be packaged in linear, the length will be 6 meters, or customized.

For the Shape "I", "C", and some simple shapes, they can be packed in rolls. 400-600 meters/roll.

For more information, please kindly search and browse our official website: https://pa.kaxitech.com Contact us if you need more details on Polyamide Profile. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Thermal Insulation、Very Thick. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : PA66 Products > Thermal Barrier Strip

Premium Related Products

Other Products

Hot Products

Universal Car Wheel Tire Valves ABS Plastic Automobile Bicycle Tyre Valve Nozzle Cap Dust Cap Wheel Tire Valve Stem CapsCutting Dies of Thermal BreaksGlass Fibre Reinforced Polyamide 66 GranulesHigh Precision Extruded Nylon Chain GuideAutomatic Non Woven Bag Making MachineNon Woven Surgical Gown Medical Dressing for Hospital or Food Industry Kxt-Sg01Disposable Non Woven Face Mask MachineDisposable Bouffant Cap Ready Made Supplier for Medical Protection Hotel and Industry Kxt-Bc01Disposable Non Woven Anti-Dust Shoe CoverDisposable Non Woven Beard CoverDisposable Earloop or Tie-on Nonwoven Face MaskI Shape 14.8mm Extruded Polyamide Thermal Break StripDisposable Non-Woven Hair Net Mob Cap Elastic Free SizeDisposable Non Woven Mob Cap Making Machine1600 2400 3200 Non Woven Machine S Ss SMS Making Machine1600mm Best Non Woven Machine S Ss SMS Making Machinery Fabric Making Line