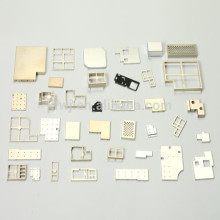

Plastic Injection Molds High Precision Spare Parts Mould Manufacturer for Plastic Products

Basic Info

Model No.: KXT-FM04

Product Description

Model NO.: KXT-FM04 Surface Finish Process: Mirror Polishing Plastic Material: PA66+GF Application: Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware Design Software: Pro-E Certification: CE, ISO, TUV Transport Package: Wooden Cases HS Code: 8480719090 Shaping Mode: Injection Mould Mould Cavity: Multi Cavity Process Combination Type: Compound Die Runner: Hot Runner Installation: Mobile Customized: Customized Origin: Jiangyin, China High Precision Plastic Injection Molds

KAXITE TECHNOLOGY--We're familiar with developing injection molds since year of 1987, carving over dozens of thousands injection molds, now we can design and develop injection molds for our customers. https://pa.kaxitech.com/m_product/150-High-Precision-Plastic-Injection-Molds.html

PRODUCT DETAILS

Important information for the plastic injection mould :

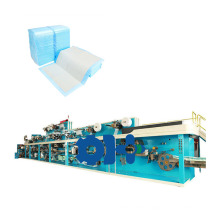

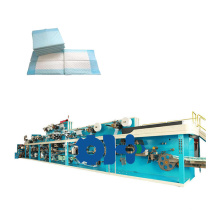

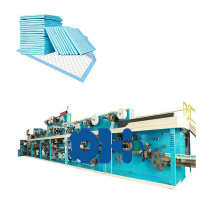

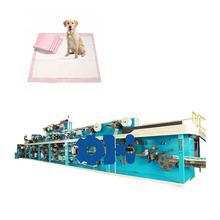

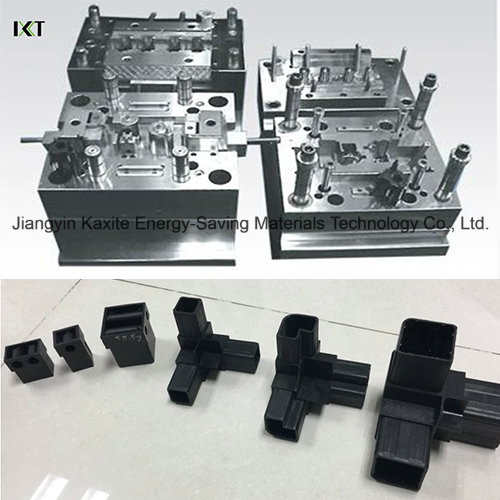

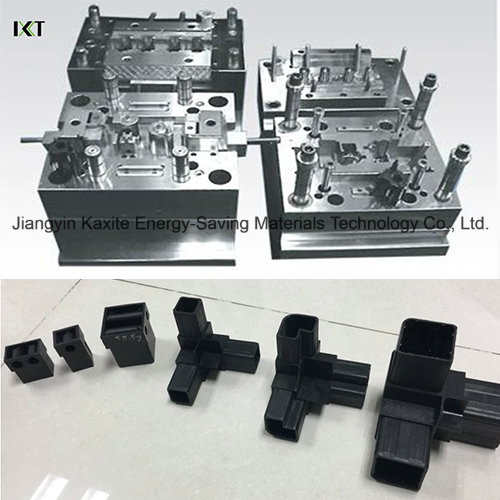

PRODUCTION SHOW

$1$

ORDER PROCESS

Our Factory Service:

1.plastic mould and metal mold making,die casting mold

2.PCBA design and development.

3.Prototype both metal and plastic

4.Low volume assembly and design review

5.Mass production for the injection molding

If you are interested in our product and want to quote, please offer 3D design drawing in STP/STL/IGS Format, Product'S material and Order Quantity.

Contact Person: Miss Amanda Zhou

https://pa.kaxitech.com/m_product/150-High-Precision-Plastic-Injection-Molds.htmlMob/:+86-152-95539599

Tel:+86-510-86990123

Contact us if you need more details on Plastic Injection. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Injection Molds、Plastic Injection Molds. If these products fail to match your need, please contact us and we would like to provide relevant information.

KAXITE TECHNOLOGY--We're familiar with developing injection molds since year of 1987, carving over dozens of thousands injection molds, now we can design and develop injection molds for our customers. https://pa.kaxitech.com/m_product/150-High-Precision-Plastic-Injection-Molds.html

PRODUCT DETAILS

Important information for the plastic injection mould :

| Mould design | According to customer request to design mold drawing |

| Plastic Part Materials | PA66+GF, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE etc |

| Design Approved | When the mold design finished,send the drawing to customer for confirm,then |

| Mold Making | Prepare the mold material,mold base,CNC machine,wire cut machine,EDM |

| Software | CAD/CAM/CAE/UG/PROE/CAD/CAXA etc. |

| Process | CNC, High speed carve, E.D.M, Wire cut, Drill, Injection etc. |

| Cavity | Single-cavity ,Multi-cavity |

| First Sample | Test the sample by ourself and assembly with our customer,analysis it and make a summary |

| First Modifying mold | According to customer request to make a modify |

| Second Sample | According to update mold,to make the second test,to check the assembly ,size whether or notfit customer request |

| Last Finish | According to customer request to solve the mold surface,or print label and logo |

| Finally Confirm | To confirm the appearance, assembly, structure |

| Use and Manufacture | According to product precision to choice the different model 80T,120T,250T,450T,800T injection machine |

| Injection Plastic Type | High speed machine,80T,120T,150T,200T,250T,350T,500T,800T |

| Mold Life | 50,000-3000,000 times |

| Injection | High speed machine,80T,120T,150T,200T,250T,350T,500T,800T |

| Runner | Hot/Cold |

| Mould steel | NAK80, 2738, 2316, H13, 718, S136, SKD61, P20,etc |

| Gate | Submarine gate, Side / Edge gate, Direct gate, Self-cutting gate ect ; |

| Lead Time | General Mold :30-40 workdays ; Large Mold:60~90 workdays |

| Supply Ability | 50 Set/Sets per Month(Small/Large/medium-sized Mold) |

| Package | Carton/Wooden Case Package or As per Customers' Requirement |

| Trade Terms | FOB Shenzhen Port, China |

| Payment term | T/T,L/C |

PRODUCTION SHOW

$1$

ORDER PROCESS

| 1.Sample/Drawing | We need your detail require clearly. |

| ↓ | ↓ |

| 2.Negotiation | Material,cavity,price,delivery time,payment term ,etc. |

| ↓ | ↓ |

| 3.Place order | According your own design or choice our design. |

| ↓ | ↓ |

| 4.Mould design | We will communicate&Exchange the opinion with you during making drawing |

| ↓ | ↓ |

| 5.Tooling mould | After custom approve the mould design will start making mould. |

| ↓ | ↓ |

| 6.Mould process | Provide photos for customer show them tooling process |

| ↓ | ↓ |

| 7.Sample confirm | Send you sample for confoirm it ,if not satisfied by customer.we modify mould . |

| ↓ | ↓ |

| 8.Delivery mould | Delivery mould after customer approve sample and arrange shipment. |

Our Factory Service:

1.plastic mould and metal mold making,die casting mold

2.PCBA design and development.

3.Prototype both metal and plastic

4.Low volume assembly and design review

5.Mass production for the injection molding

If you are interested in our product and want to quote, please offer 3D design drawing in STP/STL/IGS Format, Product'S material and Order Quantity.

Contact Person: Miss Amanda Zhou

https://pa.kaxitech.com/m_product/150-High-Precision-Plastic-Injection-Molds.htmlMob/:+86-152-95539599

Tel:+86-510-86990123

Contact us if you need more details on Plastic Injection. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Injection Molds、Plastic Injection Molds. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : PA66 Products > PA Injection Parts

Premium Related Products

Other Products

Hot Products

Universal Car Wheel Tire Valves ABS Plastic Automobile Bicycle Tyre Valve Nozzle Cap Dust Cap Wheel Tire Valve Stem CapsCutting Dies of Thermal BreaksGlass Fibre Reinforced Polyamide 66 GranulesHigh Precision Extruded Nylon Chain GuideAutomatic Non Woven Bag Making MachineNon Woven Surgical Gown Medical Dressing for Hospital or Food Industry Kxt-Sg01Disposable Non Woven Face Mask MachineDisposable Bouffant Cap Ready Made Supplier for Medical Protection Hotel and Industry Kxt-Bc01Disposable Non Woven Anti-Dust Shoe CoverDisposable Non Woven Beard CoverDisposable Earloop or Tie-on Nonwoven Face MaskI Shape 14.8mm Extruded Polyamide Thermal Break StripDisposable Non-Woven Hair Net Mob Cap Elastic Free SizeDisposable Non Woven Mob Cap Making Machine1600 2400 3200 Non Woven Machine S Ss SMS Making Machine1600mm Best Non Woven Machine S Ss SMS Making Machinery Fabric Making Line